How To Splice A Loop Into A 3-Strand Rope

In this guide we look at how to splice a loop (or eye) into the end of a piece of 3-strand rope. In this case the rope is polyester. A full video of the rope slicing steps can be seen by clicking here.

There are lots of reasons as to why you might want to splice a loop into a piece of rope, one of the most common reasons being to prepare a mooring line to fit perfectly with your deck cleats.

Luckily with 3-strand ropes, splicing is quite easy and once you have taken the time to do it once, you will not think twice about doing it again. The essential tool of the trade is a Marlin Spike, which is simply a tool to help you thread the strands of the rope easily through the rope. In the photograph below I am using a hollow shaped Marlin Spike which creates a nice path for threading the rope.

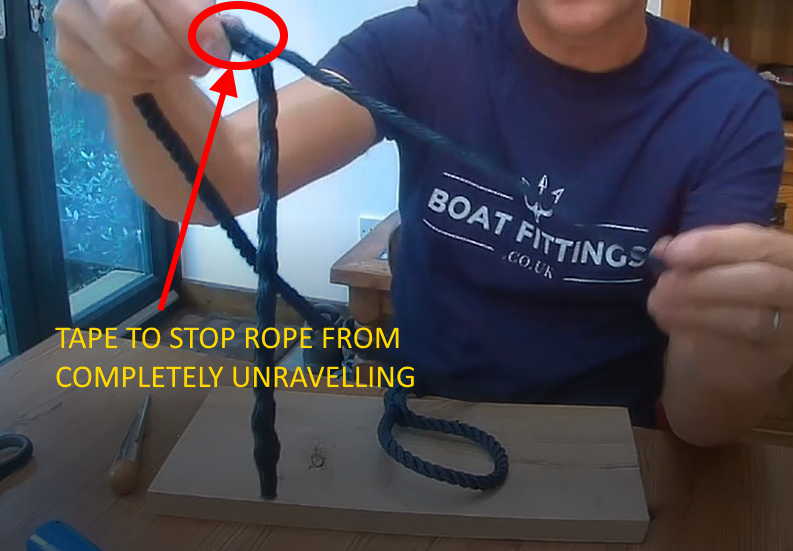

The first step is to separate the strands at the end of the rope that you want to splice but be careful, first you must put some tape around the rope at a suitable point so that the whole rope does not become unravelled.

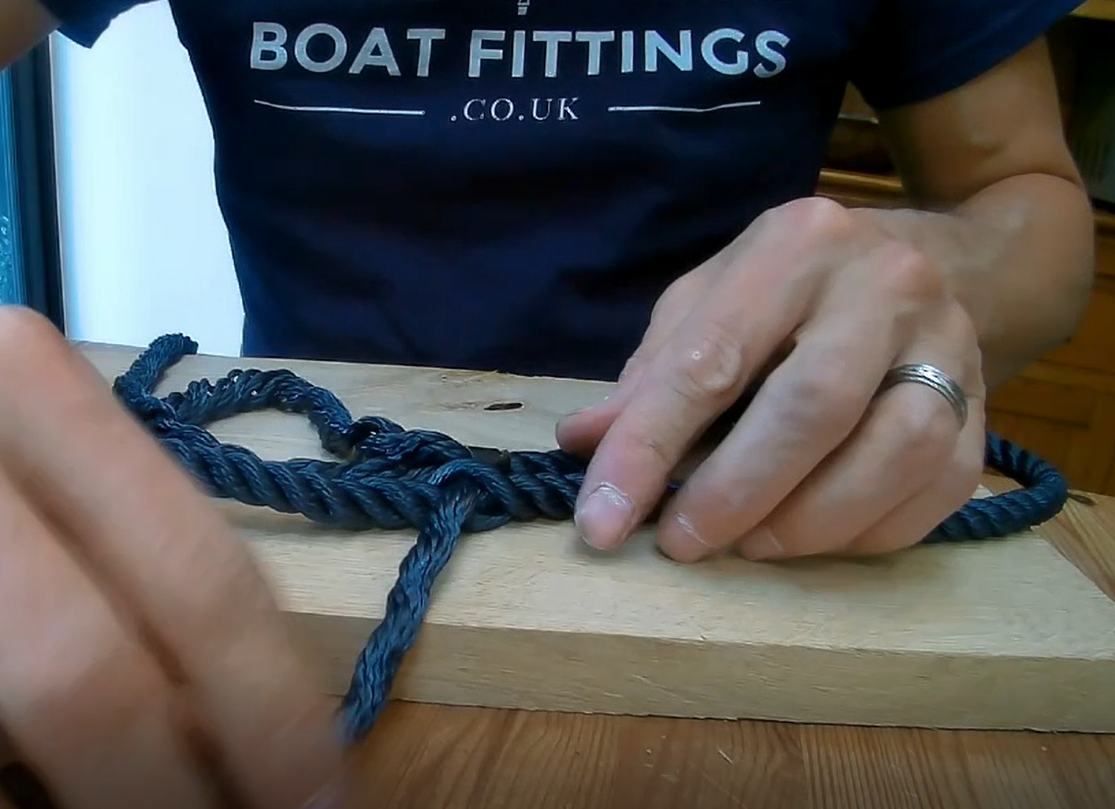

With the ropes of the 3-strand rope unravelled to the tape, we are ready to start splicing. Before each strand is spliced through the body (standing part) of the rope it is best to twist the strand a little to get it back into shape, as they initially fall into a loose baggy state which won’t look so neat as if they are twisted back into a nice compact shape.

The first strand of rope is threaded under one of the strands in the main body of the rope and pulled until tight. Beginning the splice is the easiest part, the next couple of steps are a little trickier. Each time a strand is spliced through the rope the Marline Spike is put in place first to give the rope strand a clear patch through the body of the rope. It is easiest to see the next steps in our video guide, click here to access it.

After each of the strands have been threaded (always through the standing part ie main body of the rope) it is simply a case of repeating the process until the splice is long enough. I usually splice for a length of around 8 to 10 times the diameter of the rope. Then it is a case of trimming the ends of each strand to its finished length. I first put a thin wrap of duck tape around the strand to be trimmed as close as possible to the body of the rope. Then the strand can be trimmed back with a pair of scissors.

Finally the loose ends of the strand are melted together with a flame (take great care not to let the flame near the main body of the rope). Once each of the 3 strands are trimmed and melted together the tapes can be removed.

Here we have the completed spliced eye ready for use.

If you want to purchase some 3-strand polyester rope we sell it by the meter here

If you found this guide useful or interesting you might like to sign up to our newsletter, so that we can let you know when our next guide has been published.