This is a guide for how to fit and maintain the hoses and pipes in your boat, the principals are generally the same, whether its marine engine cooling pipes, attachment to seacocks, boat cockpit drains or even tubes for fresh-water plumbing. The emphasis in this guide is safe and robust connections based on common sense and good engineering principals.

Safety Matters For Marine Pipe Fittings In Boats

Of all the checks and maintenance tasks that we perform on our boats, pipes and hose fittings should be checked every season, as in many cases these pipes and connections represent a vital seal between the inside of your boat and the sea water that we need to keep out.

Your hoses, pipes, tubes, and connections (and the fittings they are attached to – seacocks, sea toilets (heads), outdrives, fuel and gas fittings are some of the most vulnerable areas of your boat. A few precautions can make the difference between peace of mind and reliability or disaster at sea! While spending time at Brighton Marina I have seen quite a few sunken vessels being taken through the lock to the inner harbour with the aid of emergency flotation. The thought of that would be disastrous for most boat owners, let alone the thought of it happening at sea.

Compared to the substantial construction of our wooden, GRP or metal hulls, the plumbing of our boats is much less robust if not checked and looked after properly. If we have a good understanding of how things could go wrong then we are in a good position to avoid problems.

With regard to boat hoses, pipes and fittings there are main ways that our boat plumbing can fail:

- Hose comes off fitting

- Hose tears, fractures, perishes

- Fitting itself fails

To ensure that none of these happen we would sugest a methodical approach starting with the fittings at each end of the hose. If you are certain that the fittings are sound (maybe you checked or replaced them last season) then you can move to the next step. If not then the only way to propertly check the fitting is to remove the hose or pipe. Here are some potential issues to look out for:

- Excessive corrosion

- Stripped threads

- Cracking

- Stiff or difficult operation for Seacocks

- Distortion

- Adequate bighting features to secure the marine hose or pipe

If any of the above problems are found then it is probably time to purchase a new marine pipe fitting. Some styles of seacocks have a less-than-robust connection between the handle or grip wheel to the moving part of the fitting. If the operation of the seacocks is very tight then there is a risk over time that the handle or wheel could shear off during operation. Replacement seacocks are not expensive in the scheme of things (we have a good range here) so please do err on the side of caution. Here is an example of a fitting which might have looked absolutely fine before the hose was removed, but clearly needs replacing.

Once the fittings have been checked or replaced we come to the condition of the pipes or hoses. Things to look out for here are:

- Tearing or cracking

- Signs of damage if a small hose has been coerced onto a large fitting

- Kinking (that might prevent flow especially under suction)

- Internal delamination (often only visible when hose is removed)

Here are some examples of damaged hoses in need of replacement.

| Cracked Hose | Cracks After Aging | Internal Delamination |

|

|

|

When selecting new pipes or hoses it is important to get the right type of hose for the job, in terms of size, material and construction. Please seek advice from your chandler (details of hose and pipe selection are beyond the scope of this guide) but be aware that some material types are unsuitable for certain applications even if they might look fine, for example fuel lines need the correct type of plastic for resistance to diesel or petrol, drinking water hoses also need to be carefully selected to avoid a plasticy taste, and large diameter heads waste pipes need to be reinforced to avoid kinking around bends.

The internal diameter of the hose needs to be a good match to the fitting that it is going on to. It sometimes happens that there is a mismatch here, so you might have a 25mm seacocks fitting and a 20mm marine engine cooling manifold fitting. Rather than choose a hose which is either too tight at one end or too loose at the other end if is better to purchase two pieces of hose and a hose adaptor to join the two together.

Here is one example of an incorrectly fitted hose and fitting.

The left and right connections do not look too bad, but the upper hose connection has two issues. Firstly the hose is too large for the fitting, meaning the hose clip has been excessively tightened to get a seal. Secondly the chosen Jubilee clip is too large for this connection.

Fitting to Pipe / Hose Joint

When choosing fittings like seacocks or adaptor fittings it is preferable to choose one with 'teeth' or a bulge to help to mechanically keep the hose or pipe in place. Examples of such fittings are shown below.

| Size adaptor with good gripping teeth | T-Adaptor with end bulges |

|

|

If the sizing match of hose to fitting is correct, the chances are that the hose will not easily be pushed onto the fitting. This is very normal and can be helped by two steps, the first is to put a little washing-up liquid onto the inside of the hose (have a cloth handy to wipe your hand, and don't let any get onto the outsise of the hose). Hopefully with a concerted push you will get the tube properly onto the fitting. If this does not work things can be further eased by first dipping the end of the hose into some hot (just boiled) water first. In this case you will need to put the washing-up liquid onto the fitting rather than inside the hose. All being well you should have the hose or tube well onto the fitting with plenty of room for the hose clip (eg Jubilee clip) without it having to be right at the end of the hose, or near the end of the fitting.

Choice Of Pipe / Hose Securing Clips

Jubilee clips are usually used to keep pipes or hoses attached to sea-cox and other end fittings. When selecting Jubilee clips or other hose clips it is important to choose a good quality clip of the right size for the hose and made of the right material. At the very minimum the hose clip should be made of stainless steel, and preferably A4 or 316 marine grade stainless. In marine environments it does not take long for for ordinary (automotive quality) hose clips to rust. Also there are many clips in the sylte of Jubilee clips that are not of the same quality. The Jubilee clips that we sell on the boatfittings website are the genuine article and are Lloyds approved.

Some advise that 2 Jubilee clips should be used for important hose connections. If there is enough space then this gives and added level of security. However not all fittings and hoses or pipes give enough room for this to be sensibly achieved. It is better to have one will positioned Jubilee clip rather than two Jubilee clips, one nearly falling off the end of the hose and one nearly falling off the end of the fitting.

Below are some examples of some typical errors with hose to fitting installations:

| Rusted (non-marine) hose clips | Pipe is bearly onto fitting | Middle pipe is too large diameter for the fitting | Two hose clips will not fit here |

|

|

|

|

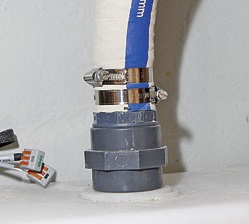

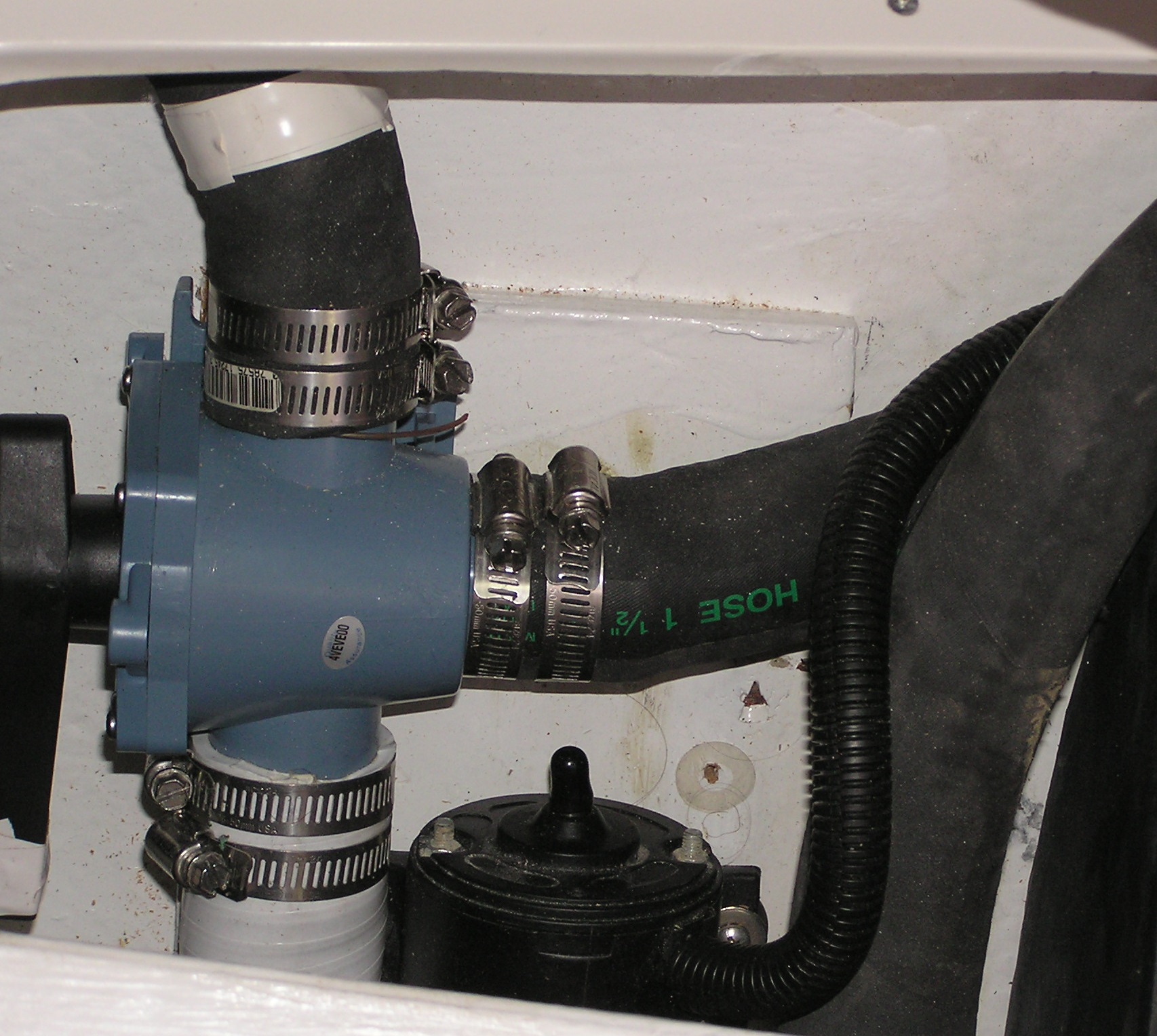

Below are some examples of some well made connections:

|

|

|

If you would like any further advice please do not hesitate to get in contact with us here at Boatfittings by phone or email.

If you found this guide useful or interesting you might like to sign up to our newsletter, so that we can let you know when our next guide has been published.

0 Items £0.00

0 Items £0.00