How To Fit A Kill-Switch

How Do You Fit A Kill Switch To An Outboard Motor? (This Guide Is For The Normally Open-Circuit Type Of Kill-Switch)

There are two main kinds of kill-switch that need to be installed in different ways, from the outside they might look the same, but electrically they work in a kind of opposite sense. In this guide we look at the type of kill-switch which is normally open-circuit, meaning that when the lanyard is in place the contacts of the kill switch are apart (known as open-circuit), when the lanyard is pulled out the contacts close the circuit.

Kill switches and kill cords are essential safety equipment for speedboats / ribs and many other types of boat.

The kill cord or lanyard is usually attached to the kill switch at one end, and the driver’s leg at the other end. If something goes wrong the driver is dislodged from his driving position the cord is pulled away from the kill-switch allowing the sprung switch to operate.

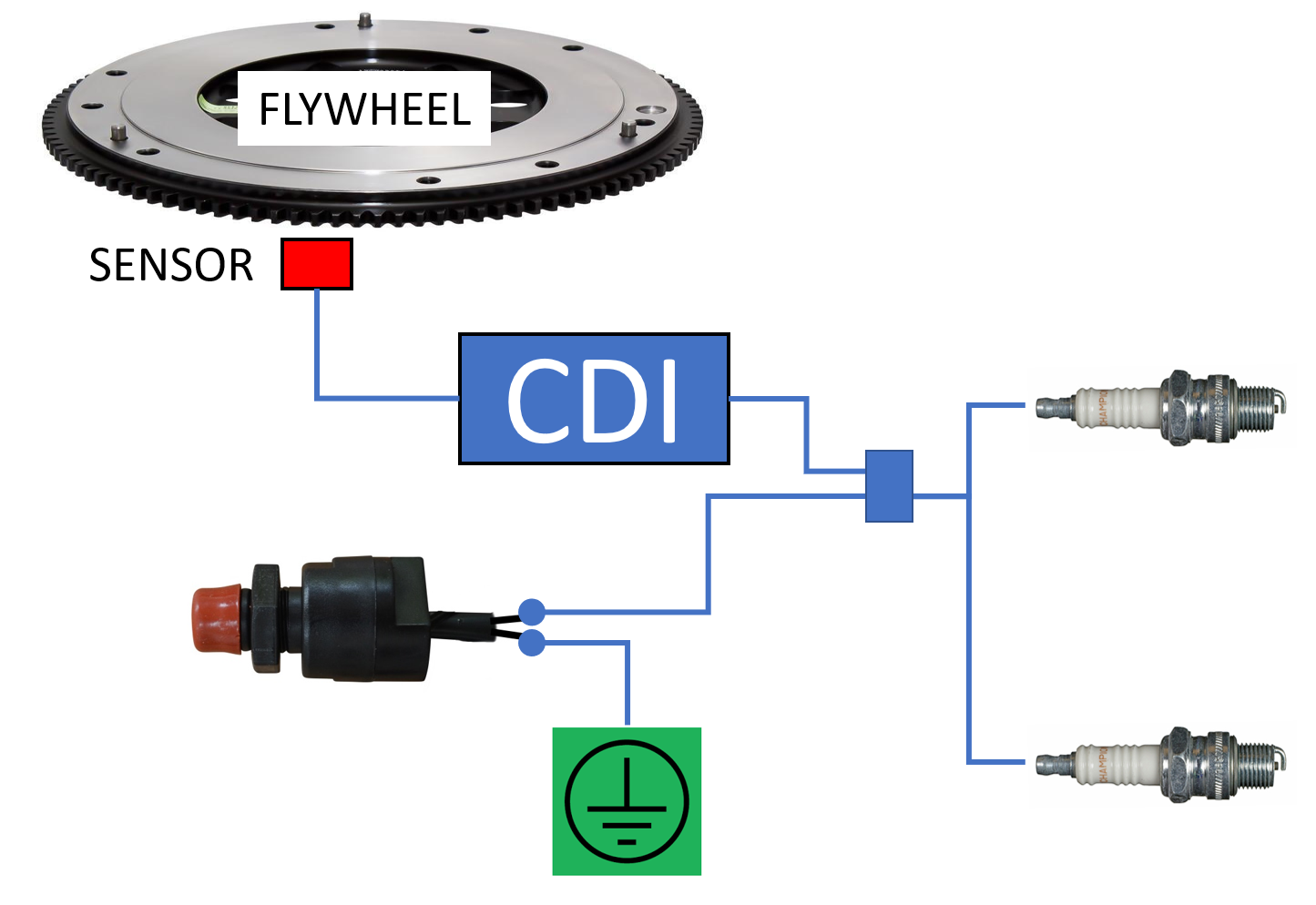

This type of kill-cord installation works on the principal of shorting out the ignition to the spark plugs. Other types of installation work on the alternative principal of turning off the ignition circuit.

Of course it is essential to wire the kill-switch correctly into the motor electrical system, which can be a bit confusing, especially as the wiring on one outboard motor can look different to the wiring on another. By explaining the principals of operation, and showing a couple of examples we hope to make life a bit easier if you are trying to install (or replace) a kill-switch yourself.

How does a kill-switch it work? (the normally open-circuit type)

A kill-switch is a very simple device that relies on a spring-loaded button to keep the switch open (ie off) when you want the engine to run. There is a clip which fits under the button of the kill-switch and the clip is attached to a tether which is also attached at the other end to the person controlling the boat. If the person driving the boat falls overboard the tether pulls the clip out and the kill switch snaps shut into its closed-circuit position (ie turning the switch on). This closed (or on) circuit has the effect of shorting out the spark-plugs, and with no sparks the engine very quickly stops.

Older outboard motors tend to have a "points and condenser" system for generating the electrical spark and for this type the kill-switch is sometimes specified as one for magneto ignition systems. The more modern outboard

motors have a slightly different way of generating the spark, which is called a CDI unit. CDI stands for Capacitive Discharge Ignition, and without going into detail the CDI system has the equivalent effect of the points and condenser system which is to provide a high voltage charge to the spark-plugs at just the right time to ignite the fuel and air mixture and power the engine. A kill-switch stops the engine by diverting the charge which would normally power the spark-plug.

A schematic wiring diagram is shown below:

The kill-switch can be fitted directly to the outboard motor on smaller boats, but on larger boats where the controls and steering are a way from the motor, the wiring needs to be routed from the outboard motor to a suitable place on the console. Mounting the switch to the boat means than one switch can serve several engines.

If your engine is already fitted with a push-button stop switch, all you have to do is disconnect the wires from the push-button stop switch and attach the wires to the kill switch.

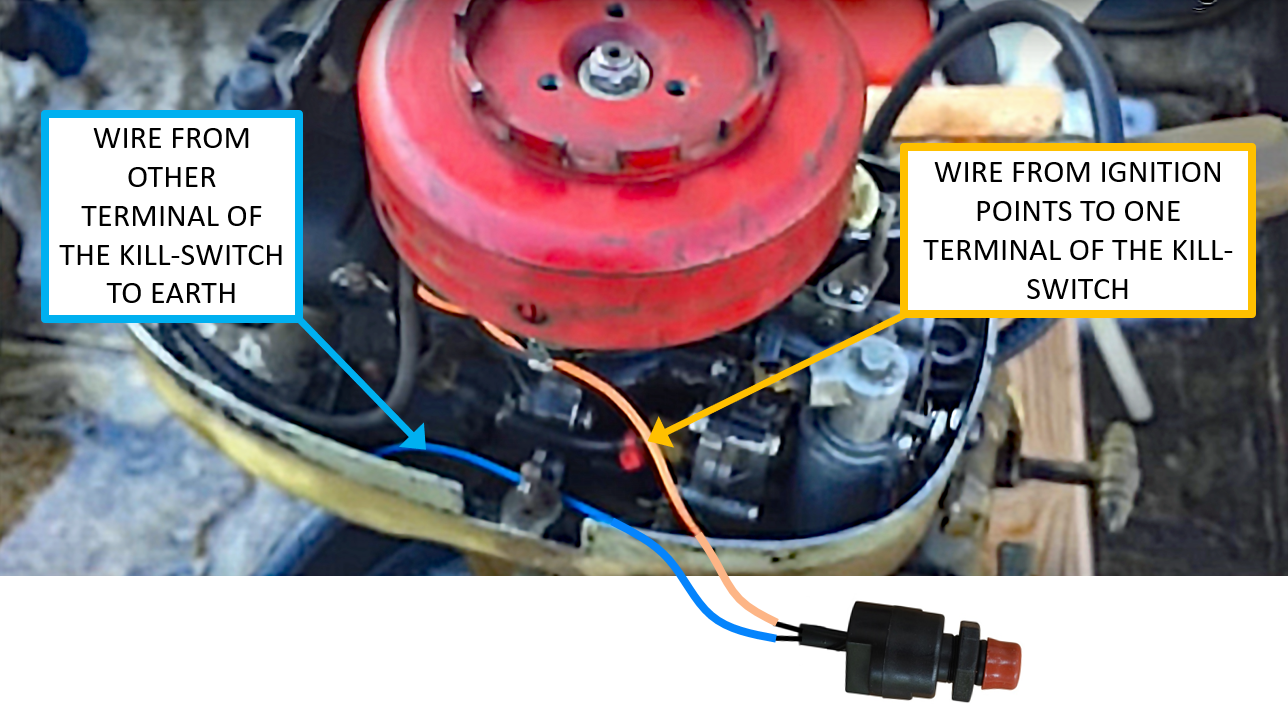

Below is an example showing how a kill-switch can be installed in an older points and condenser outboard-motor.

The kill-switch is physically mounted to the front of the outboard motor casing (shown schematically here for clarity). One wire is taken from the ignition points to a terminal of the kill-switch. The other wire is taken from the other terminal of the kill-switch to the metal casing of the outboard motor (earth). Care needs to be taken to make sure that neither of the wires can get caught up with the flywheel under all conditions.

One final thought. If you fit a kill switch, you should also have at least one spare lanyard that lives in a known place on the boat. The main reason for this is that if the driver of the boat goes overboard (with his lanyard) then of course the engine stops as it should do, but anyone who is still on the boat will need the spare lanyard in place to re-start the engine and hopefully rescue the man overboard.

If you found this guide useful or interesting you might like to sign up to our newsletter, so that we can let you know when our next guide has been published.